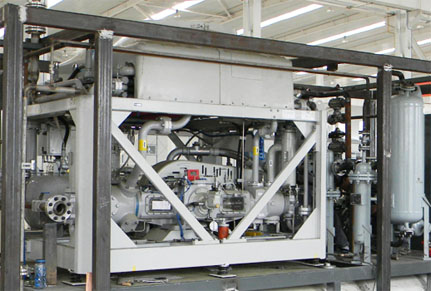

Skid CNG Equipment

At present, there are two natural gas sources: one is directly explored from natural gas field; another is through coal gasification.

Natural gas from field exploitation need to first be purified before transported to gas station, or first be made into CNG.

Syngas made from coal gas or coke oven gas needs methanation reaction to convert CO and CO2 to methane. Methane is purified to be changed into natural gas through pressure swing adsorption technology, and then changed into compressed natural gas (CNG) by by pressing.

Syngas made from coal gas or coke oven gas needs methanation reaction to convert CO and CO2 to methane. Methane is purified to be changed into natural gas through pressure swing adsorption technology, and then changed into compressed natural gas (CNG) by by pressing.

UNE has unique technologies in CNG production from both natural gas sources mentioned above, and has plenty of experience in real projects. UNE can also provide high efficiency, stable skid CNG equipment, which is characterized as follows:

High integration, less occupation area;

Easy site installation and fast station establishment;

Complete explosion proof design, safe and reliable operation;

High degree of standardization, low operation and maintenance cost;

Easy operation and maintenance, high degree of automation;

Skid integration design, separable to install and use;

Stable operation, low noise, high efficiency and energy saving;

PLC automatic control, high degree of digitization, long-distance data transmission available;

Equipment of gas filling island form, flexible arrangement to meet the needs of different stations.