Hydrogen Production Equipment

UNE owns a variety of hydrogen production technologies, and can provide full set of equipment. According to the specific circumstances of customers, we use different materials and optimize process, thus reduce customer cost and maximize customer value.

Light Hydrocarbon Steam Reforming Process and Technology to Produce Hydrogen

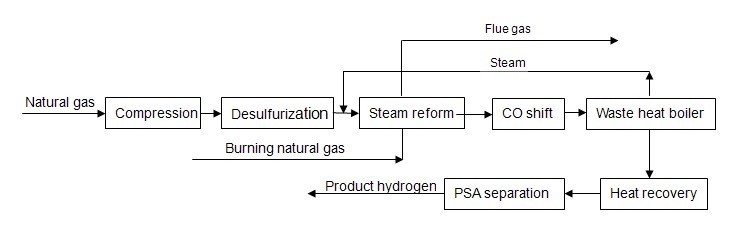

Typical PFD of producing hydrogen from natural gas is as follows:

- Low cost, suitable for large scale hydrogen users;

- Optional pressure of product hydrogen within 0.6~3.0MPa;

- Raw materials can be light hydrocarbon, such as natural gas, naphtha, etc.

PSA Hydrogen Production

Technology overview:

The principle is that at normal temperature, special adsorbent (such as: activated carbon, silica gel, molecular sieve, alumina, or combinations thereof) adsorbs impurities (such as: H2O, CO2, H2S, CO, CH4, N2, etc.) in hydrogen gas mixture under higher pressure and desorb under lower pressure. Hydrogen which is hard to adsorb will penetrate adsorbent bed and is concentrated (or refined). Multiple program-controlled vessels is used to realize continuous process of feed gas and yield product.

Merits of the technology:

1. Advanced and reliable technology that assures high yield of hydrogen with low energy consumption. Purity can vary from 80~99.999%;

2. Large process capacity: from 30 to 12000 Nm3/h;

3. The plant can be operated stably within 30~110% of its design capacity without reducing purity of hydrogen

4. Simple operation, highly-automated, easy to start and shutdown;

5. The special program control valve switches fast, and is highly reliable with long lifetime;

6. Optimized software can realize tower shifting without shutdown.

Applicable In:

Purification of mixed hydrogen gas, such as: shift gas, released gas from synthetic ammonia, methanol tail gas, coal gas, ammonia pyrolysis gas, catalytic dry gas, refined gas, membrane separated gas, reformed gas, coke oven gas, etc.

The process can be designed according to customers’ requirements on purity and pressure of hydrogen.

Projects:

Xuchang Ruida Chemical Co., Ltd. 3000Nm3/h hydrogen production by natural gas reforming

Jiangxi Changjiu Changyu Chemical Engineering 2000 Nm3/h hydrogen plant (shift gas)

Taigong Tiancheng Technology Co., Ltd. 30000Nm3/h comprehension utilization of coke oven gas project

Hydrogen Separation from COG

Technology overview:

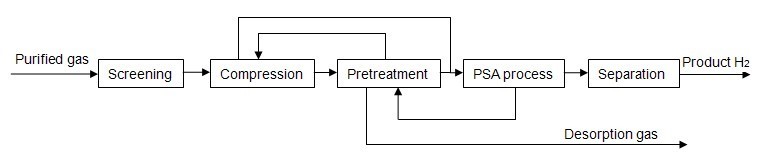

Taking coke oven gas as raw material, 99~99.999% hydrogen can be produced after processes of desulfurization, removal of benzene and naphthalene, compression, pretreatment, and then after separation and purification by PSA.

Merits of the technology:

- Reliable and mature technology, widely used in steel industry;

- Low cost, suitable for large-scale hydrogen users;

- The pressure of hydrogen can vary between 0.6 to 3.0MPa.

Light Hydrocarbon Steam Reforming Process and Technology to Produce Hydrogen

Technology overview:

Typical PFD of producing hydrogen from natural gas is as follows:

Merits of the technology:

- Low cost, suitable for large scale hydrogen users;

- Optional pressure of product hydrogen within 0.6~3.0MPa;

- Raw materials can be light hydrocarbon, such as natural gas, naphtha, etc.

Projects:

PSA Hydrogen Production

Technology overview:

The principle is that at normal temperature, special adsorbent (such as: activated carbon, silica gel, molecular sieve, alumina, or combinations thereof) adsorbs impurities (such as: H2O, CO2, H2S, CO, CH4, N2, etc.) in hydrogen gas mixture under higher pressure and desorb under lower pressure. Hydrogen which is hard to adsorb will penetrate adsorbent bed and is concentrated (or refined). Multiple program-controlled vessels is used to realize continuous process of feed gas and yield product.

Merits of the technology:

1. Advanced and reliable technology that assures high yield of hydrogen with low energy consumption. Purity can vary from 80~99.999%;

2. Large process capacity: from 30 to 12000 Nm3/h;

3. The plant can be operated stably within 30~110% of its design capacity without reducing purity of hydrogen

4. Simple operation, highly-automated, easy to start and shutdown;

5. The special program control valve switches fast, and is highly reliable with long lifetime;

6. Optimized software can realize tower shifting without shutdown.

Applicable In:

Purification of mixed hydrogen gas, such as: shift gas, released gas from synthetic ammonia, methanol tail gas, coal gas, ammonia pyrolysis gas, catalytic dry gas, refined gas, membrane separated gas, reformed gas, coke oven gas, etc.

The process can be designed according to customers’ requirements on purity and pressure of hydrogen.

Projects:

Xuchang Ruida Chemical Co., Ltd. 3000Nm3/h hydrogen production by natural gas reforming

Jiangxi Changjiu Changyu Chemical Engineering 2000 Nm3/h hydrogen plant (shift gas)

Taigong Tiancheng Technology Co., Ltd. 30000Nm3/h comprehension utilization of coke oven gas project

Hydrogen Separation from COG

Technology overview:

Taking coke oven gas as raw material, 99~99.999% hydrogen can be produced after processes of desulfurization, removal of benzene and naphthalene, compression, pretreatment, and then after separation and purification by PSA.

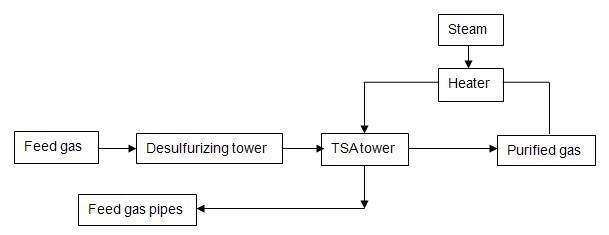

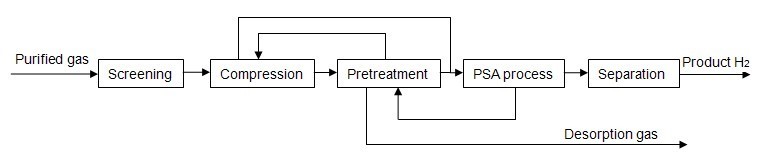

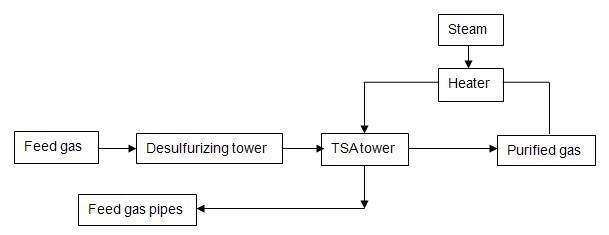

Typical process of hydrogen production from coke oven gas is as follows:

2. Hydrogen separation

Merits of the technology:

- Reliable and mature technology, widely used in steel industry;

- Low cost, suitable for large-scale hydrogen users;

- The pressure of hydrogen can vary between 0.6 to 3.0MPa.