MDEA Deacidification Technology

Technology Overview

Compound amine solution technology is applicable in acid gas removal of natural gas, shift gas, refinery gas, urban coal gas, coke oven gas, etc.

The technology adopts compound amine solution by adding activator in MEDA solution, it has both physical and chemical adsorptivity, the physical property of which can achieve desorption and regeneration under atmospheric pressure, and the chemical property of which can get thermal regeneration of a small amount of solution, and ensure the purity of gas. Therefore the technology has low heat consumption and high purification performance; it can remove the inorganic sulfur of sulfur-bearing gas, and meanwhile hydrolyze the organic sulfur.

Organic amine desulfurization process

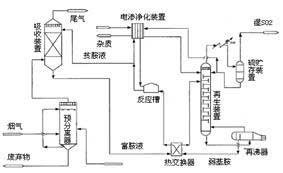

The desulfurization process of organic amine is composed of a pre separator, an absorption device, a desorption device and an amine purification device.

Features

Our proprietary solution formula and patented packed tower make the technology have the features below:

High purity: CO2≤2ppm, H2S≤1ppm;

Low thermal consumption;

The solvent is not corrosive to carbon steel;

Low investment and simple operation

Main Application

CO2 removal of natural gas, matching piped gas or LNG plant;

H2S removal of natural gas, matching piped gas or LNG plant;

Selective H2S removal of natural gas, matching piped gas;

CO2 removal of shift gas, matching synthetic ammonia, methanol or cryogenic separation system;

CO2 removal of synthetic gas, matching synthetic ammonia, methanol or cryogenic separation system;

CO2 and H2S removal of coke oven gas, matching LNG plant;

CO2 and H2S removal of coal bed methane, matching LNG plant.

Projects

Shenran (Taian) 15×104 Nm3/d acid gas removal of natural gas, matching LNG plant;

Ganghua (Jincheng) 60×104 Nm3/d acid gas removal of coal bed methane, matching LNG plant;

Taigong Tiancheng 72×104 Nm3/d acid gas removal of coke oven gas, matching LNG plant.